Slash Energy Costs And Eliminate Safety Risks With ONE DEVICE!

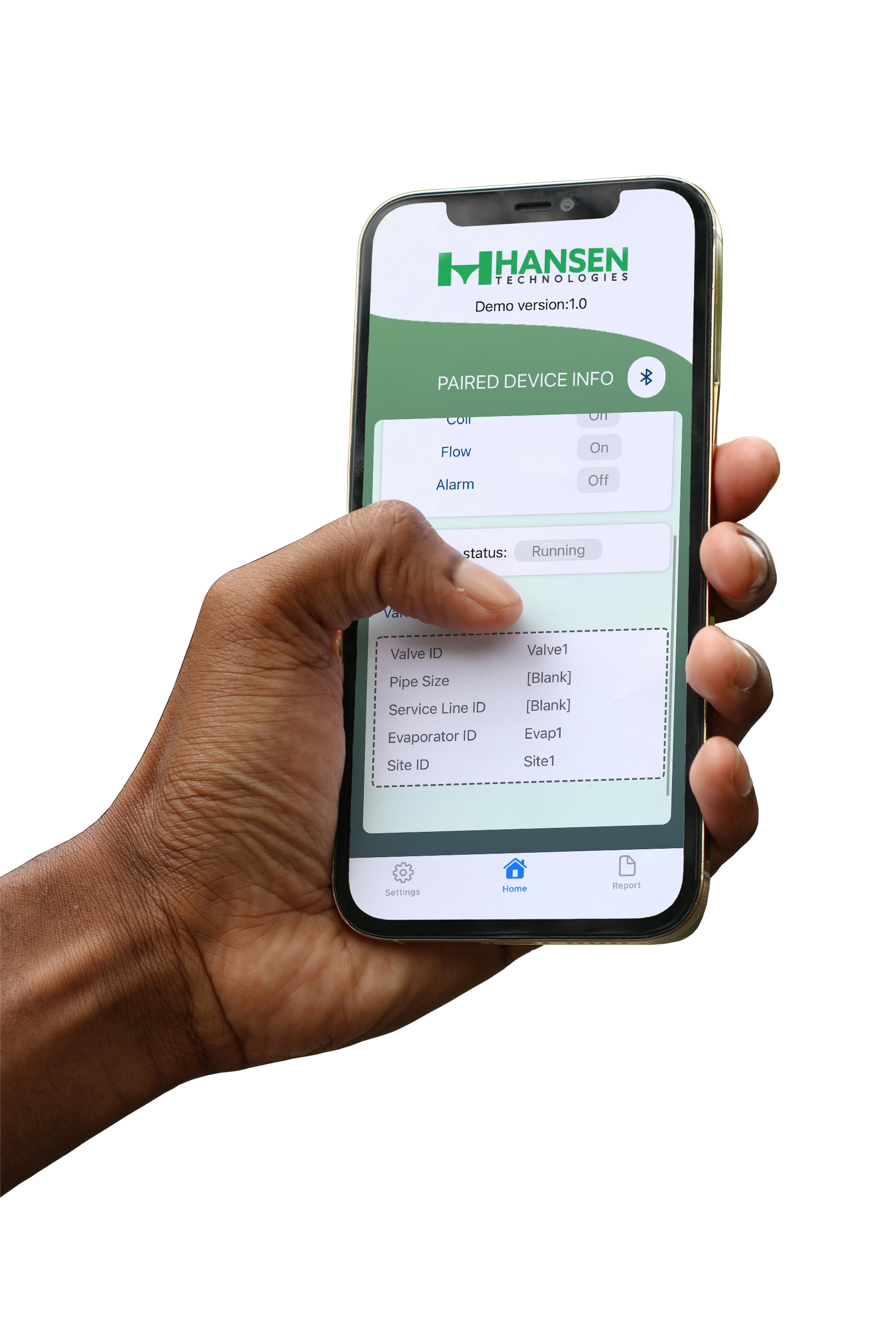

Sentinel is a patented and unique technology that identifies and eliminates safety, efficiency and compliance issues associated with aging valve installations, regardless of make, model or fluid/refrigerant type.

4 Reasons Your System Needs Sentinel

Unlock Hidden Energy Savings

Energy Savings ROI Payback in 3-Years or Less!

A single valve leaking by, unnoticed, can cost over $5,000 in energy annually. Sentinel Activity Monitoring can detect energy waste (parasitic loads) in industrial refrigeration system by providing confirmed valve status.

Eliminate Unseen Safety Risks

“My job is to keep my company out of the news.”

- Facilities Manager for large national distribution end-user

A catastrophic safety event can easily cost a business millions of dollars or even force it to close. Sentinel Activity Monitoring can improve safety by ensuring all critical industrial refrigeration valves are working as designed.

Maximize Uptime

“If the production line is not up, somebody is going down!” ...said every plant manager ever.

In some food production facilities, a hour of down-time can easily exceed $100,000. Sentinel Activity Monitoring can greatly reduce unexpected down-time by identifying system anomalies, such as intermittent loss of flow, internal by-pass, burned-out solenoid coils and slow opening/closing valves in industrial refrigeration systems.

Commit to Compliance

“OSHA is here, and they want to know if critical to safety valves are being properly tested.”

When OSHA stops by, its typical fine amount is $33,000. Sentinel Activity Monitoring provides the only means of on-going non-intrusive valve testing and automated documentation.

Let's discuss how Sentinel could improve your current system.

Contact our sales team.