Reliable. Efficient. Compact.

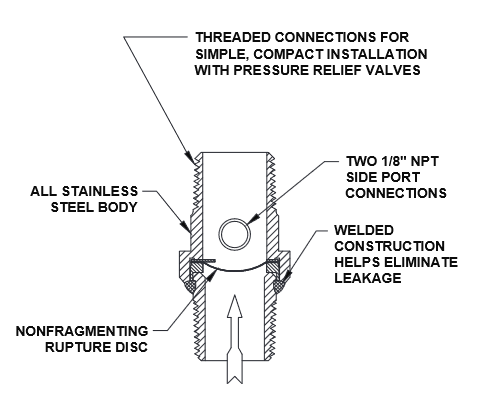

These rupture disc assemblies are typically used between a vessel (or 3-way valve) and a pressure-relief valve. They must be used for atmospheric, not differential, pressure-relief. Rupture disc assemblies are required when using Hansen pressure-relief valves for halocarbon applications because the high cost of such refrigerants demands extreme tightness.

CONTACT US Copyright © 2016-2024 Hansen Technologies Website by Solve Your Marketing & i6 Graphics