Wireless Lights. CSA Certified. Advanced Design.

Encapsulated Hansen standard coil.

Teflon main & pilot seats.

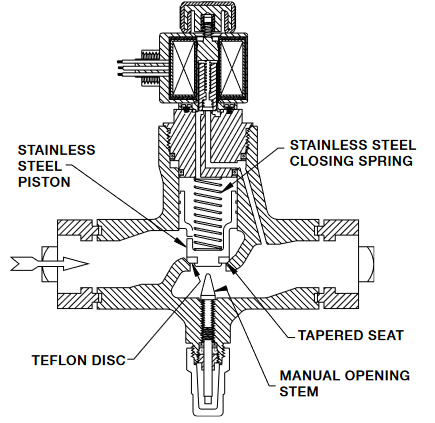

Power saving, low-wattage molded coil; Teflon seats; stainless steel trim including piston; spring-closing; double seal manual opening stem. One standard molded coil fits all Hansen valves.

Protect interior of valve from dirt during installation; normally use close-coupled inlet strainer. Allow 2.25” (57mm) above valve for coil removal, 3” (76 mm) below strainer for screen removal. Match arrow on body with system flow direction. If a pressure reversal can occur, as during hot gas defrost with liquid recirculation, use a check valve on the outlet side of the HS7. For proper flange gasket sealing, care must be taken when threading or welding to assure flanges are parallel to each other and perpendicular to pipe. Also, gaskets should be lightly oiled and all bolts must be tightened evenly.

CONTACT US Copyright © 2016-2024 Hansen Technologies Website by Solve Your Marketing & i6 Graphics