National Board Certified. Eliminates Hazards. Facilitates Compliance.

Detects and indicates when a relief valve lifts

LED Indication:

Bright LED with 360° visibility

Battery operated, 7+ years life

Blinks for 2+ weeks after a lift

Not for retrofit on existing valves

No setup, calibration, or wiring required

No false detection

Valve is National Board Certified

No change in capacity ratings

No piping change

Drop in replacement for existing valves

Intended for one-time use

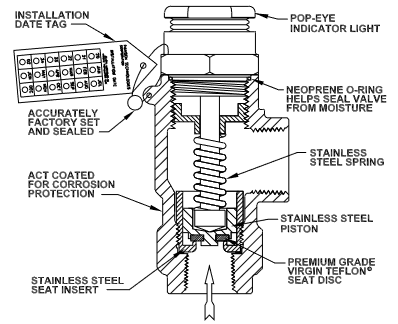

Hansen pressure-relief valves help meet the requirements of ANSI/ASHRAE 15 Safety Standard for Refrigeration Systems as well as other worldwide codes. This standard requires pressure vessels of all refrigeration systems to be protected by a pressure-relief device or other

approved means to safely relieve pressure in the event of fire or other abnormal conditions.

Once installed, a properly selected Hansen pressure-relief valve is ready to vent to atmosphere any temporary excessive overpressure inside of a vessel. After discharge, these valves will attempt to reseat to minimize loss of refrigerant. However, once any relief valve has discharged, it must be replaced as soon as possible because debris may have settled on the seat during discharge.

CONTACT US Copyright © 2016-2024 Hansen Technologies Website by Solve Your Marketing & i6 Graphics