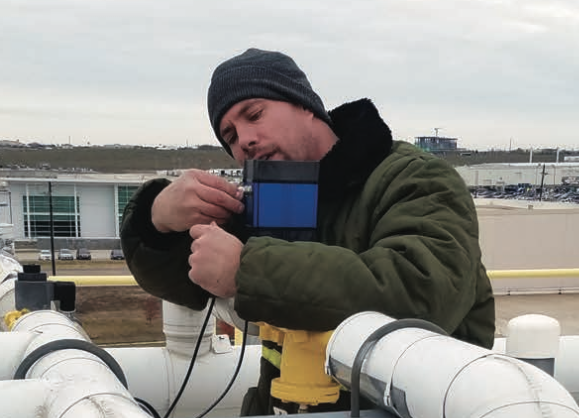

Joe Cole oversees banana ripening rooms for a major US retailer. Banana ripening is a detailed and precise process. The room must be kept at a consistent humidity level and temperature over five to seven days to ensure proper ripening. Utilizing 20 motor control valves, Joe was experiencing issues with power head function due to moisture build up in some of his units. Motors were overheating and intermittently shorting out. When Joe contacted Hansen, they suggested that his facility participate in a field test for the newly designed Hansen Motorized Control Valve (MCV). Joe was provided with MCV conversion kits to upgrade

his existing control valves.

Converting the existing valves to the new MCV which virtually eliminates the potential for moisture build-up and results in much more reliable and precise operation overall.

Improvements were noted in these key areas: Motor actuator housing, function, forward-facing digital readout, and an improved power cable with stronger connections. The molding appeared more secure, as well, and the housing seal now eliminates moisture inside which, in the past, contributed to shorting. Together these factors provide more reliable functionality all around. An additional benefit Joe noted in the new construction is that the indicator light is helpful in letting you know when you’re in the program settings.

“Hansen’s technical support is excellent. Hansen responds quickly and comes to our facility immediately when needed. Hansen techs have a wealth of knowledge and extensive operational backgrounds. It’s obvious that Hansen representatives have worked in the field. We found them to be very detailed in their evaluation of our needs and in troubleshooting unique solutions. We will continue working with them.”

Joe Cole – Refrigeration System Engineer, major US retailer

52-foot trailer banana ripening rooms

Moisture in power head housing causing intermittent shorting of valves

Hansen’s new MCV replaced Joe’s problematic valves.

Improvements noted in these key areas:

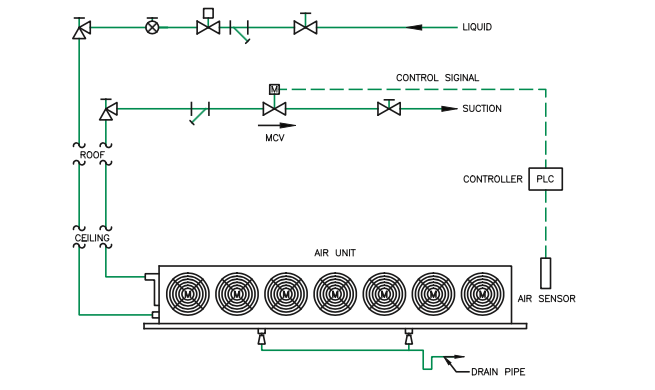

1″ (20mm) Port Size, MCV20 Motorized Control Valve

Suction Control Valve

Refrigeration Load: 7.5 Tons (26.4kW)

Suction Temp: 45F (7.2C)

Room Temperature: 56F (13C)

Liquid Supply: 140 psig (9.6 bar), sub- cooled to 40F (4.4C)

CONTACT US Copyright © 2016-2024 Hansen Technologies Website by Solve Your Marketing & i6 Graphics