Reliable. Flange-Bodied. Heavy Duty.

These reliable, flanged bodied valves are ideal for use as standard, stock refrigerant solenoid valves.

While primarily for ammonia, these valves are also suitable for R22, R134a, CO2 and other approved refrigerants.

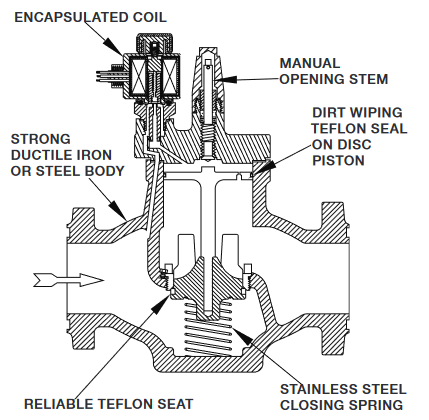

These valves combine modern design and new age materials with advanced manufacturing techniques and intense quality control to offer a significantly superior and reliable product. Their ductile iron bodies are stronger and more rugged than common cast iron, including semi-steel (class B iron) valves.

They are more dirt resistant than full skirted piston designed valves and use a single, standard, power saving, low wattage coil that can be used on all valve sizes. All valves incorporate reliable teflon seating and stainless steel spring closing. Non-asbestos gaskets are standard. Main seats are stainless steel on 1½” and larger valves. All valves use a spring activated,

teflon, dirt-wiping piston seal. Manual opening stems are located on top of valves, up and away from dirt and rust particles to extend stem seal life.

This also facilitates easier insulating of valves. Each valve is individually packaged or sealed for valve interior cleanliness and ease of storage until ready for use. All valve boxes are clearly marked with catalog numbers

and description.

CONTACT US Copyright © 2016-2024 Hansen Technologies Website by Solve Your Marketing & i6 Graphics